Hot Air Rework Station

Hot air rework stations from Precision PCB Services, Inc. are a popular choice for multiple applications. Clients in a diverse cross-section of industries use them to repair, rework and manufacture surface-mounted PCB devices. They allow technicians to quickly, and with a high degree of accuracy, perform rework tasks such as replacing a defective components, reballing BGA Components, and installing an array of Surface Mount Devices, (SMD).

The right hot air rework station can go a long way towards improving product consistency, reducing waste and enhancing productivity in your operation. We design all products with today’s engineers and technicians in mind. Packed with features that enhance your workflow, our rework stations offer innovation and superior performance at an affordable price point.

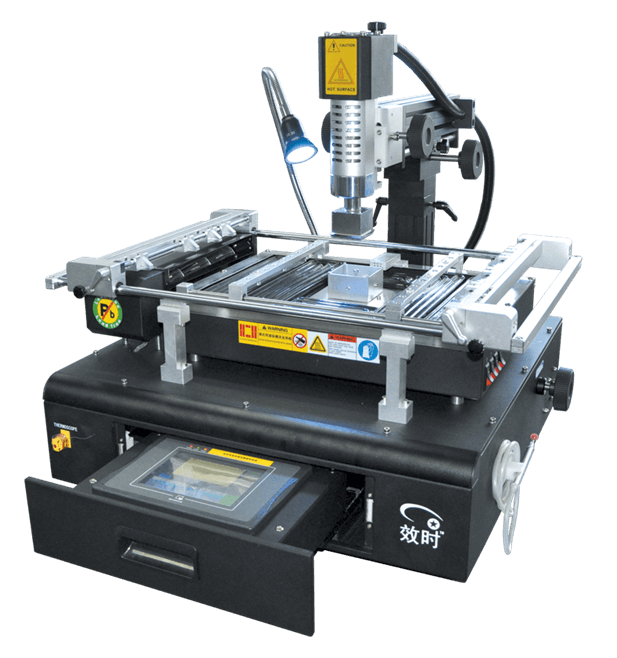

SP360C BGA Rework Station - Discontinued

A great entry-level BGA Rework Station for jobs that don't require a split vision assist camera.

Fits Boards up to 16.5"

Places components from 4mm to 55mm

RW-B400CBGA Rework Station

A great entry level BGA Rework Station for jobs that don't require split vision assist camera.

Fits Boards up to 17.5"

Places components from 4mm to 55mm

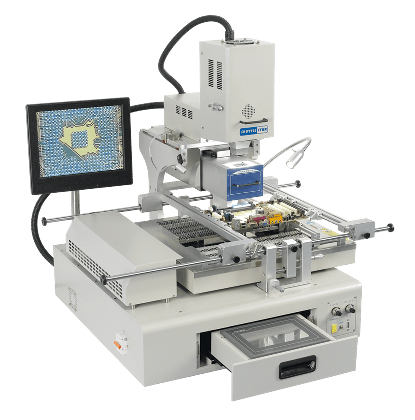

SV530 Split Vision BGA Rework Station - Discontinued

High Resolution Vision System

Fits Boards up to 25"

Places components from .22mm to 120mm

SV550 Split Vision BGA Rework Station

High Resolution Vision System

Fits Boards up to 25"

Places components from 6mm to 60mm

SV560 Split Vision BGA Rework Station

High Resolution HDMI Vision System

Fits Boards up to 36"

Places components from .22mm to 80mm

SV560-A Split Vision BGA Rework Station

High Resolution HDMI Vision System

Fits Boards up to 36"

Places components from 1mm to 80mm

Auto Pik n Place.

Motorized X, Y and Theta controls.

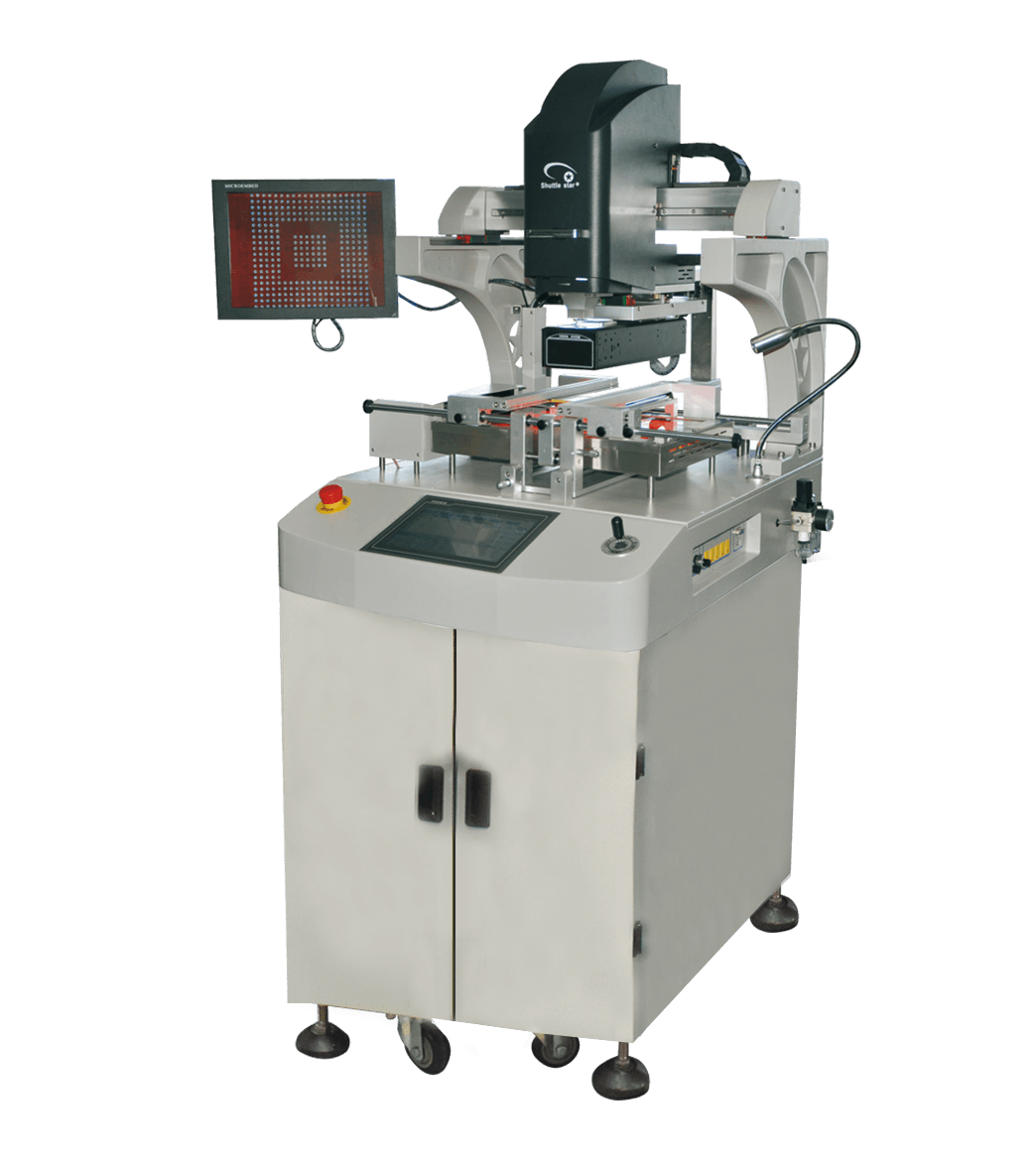

Split Vision BGA Rework Station

E6250U - Nitrogen Gas Capable

Uses compressed air or Nitrogen.

High Resolution HDMI Vision System

Fits Boards up to 36"

Places components from 1mm to 80mm

Auto Pik n Place.

Motorized X, Y and Theta controls.

Joy Stick and Touch Screen Control

Movable Bottom Spot Heater

E6250U Nitrogen Capable SMD & BGA Rework Station with Cabinet

Same specs as the E6250U BGA Rework Station listed above.

Only this one gas a movable cabinet base on wheels.

Contact us for pricing

Why Choose a Hot Air Rework Station?

Hot air-type units are the most popular variety of SMD rework stations on the market today. They tend to offer better value than IR stations, in part because lower-priced infrared units often use poor-quality components that lead to decreased accuracy.

Additionally, because of their ubiquity, more technicians are trained to use hot air-type stations. As a result, if you’re adding to your facility or replacing an aging unit, a hot air station will require less time and expense to onboard.

World-Class Support for Your Purchase

Precision PCB Services is known for both high-quality hot air rework stations and comprehensive support that helps our clients meet their goals. We are dedicated to being your partner for life. That means our obligation to you doesn’t end after the sale. We can provide general consulting and service as well as training for your team to help you make the most of your purchase.

We also back all of our products with lifetime technical support and one of the best warranties in the business.

Hot Air Soldering Work

Precision PCB Services’ hot air soldering rework stations are fully self-contained with their own internal air and vacuum except for the E6250U that requires an external air or nitrogen source. Various models are capable of fitting boards up to 36”. Standard, high and ultra-high-definition vision systems are available alongside nitrogen-capable units.

Available soldering equipment includes a seven-piece nozzle set, multiple sizes of component pickup tubes and a universal reball fixture, among other options. Need help choosing the right station for your application? One of our knowledgeable sales representatives would be happy to go over your requirements and recommend a comprehensive solution that’s right for your budget.

How Do I Use a Hot Air Rework Station?

Use your hot air rework station for any operations you wish to perform on your PCB, from general PCB assembly to ball grid array repair. For example, you can use your hot air rework station to upgrade your PCB by adding brand new components. You can also use it when you have polarized components to separate them from the board, reverse their position and return them to the board quickly.

You can use your hot air rework station to perform heat-shrink to make wire connections more secure. You can also use it to secure a replacement component to the board should one become missing or damaged.

A hot air rework station makes it easy to remove or repair any defective parts, tombstone parts (parts secure only on one side) or cold joints (parts that are not secure but may not be sticking up). You can even use your hot air gun to remove excess solder with the right tools.

To use your hot air rework station, simply choose the appropriate nozzle to fit the area you wish to apply heat to. Turn on the station, set the airflow and temperature dials to your desired parameters and go to work. Be sure to keep the gun moving so that you don’t accidentally overheat a component. When you have started the reflow and positioned your part, shut down the station by switching the power off. Be sure to clean off the board to get rid of any excess flux once the job is complete.

Request a Quote or More Information

Discover for yourself why Precision PCB Services is the leading partner to contract manufacturers, medical, aerospace and silicon chip manufacturers, PCB repair facilities, research and development laboratories, and more.

Find detailed specifications and current prices for our lineup of SMD rework stations by following the links on this page. To request a quote for a complete package of equipment and accessories, contact our office directly.