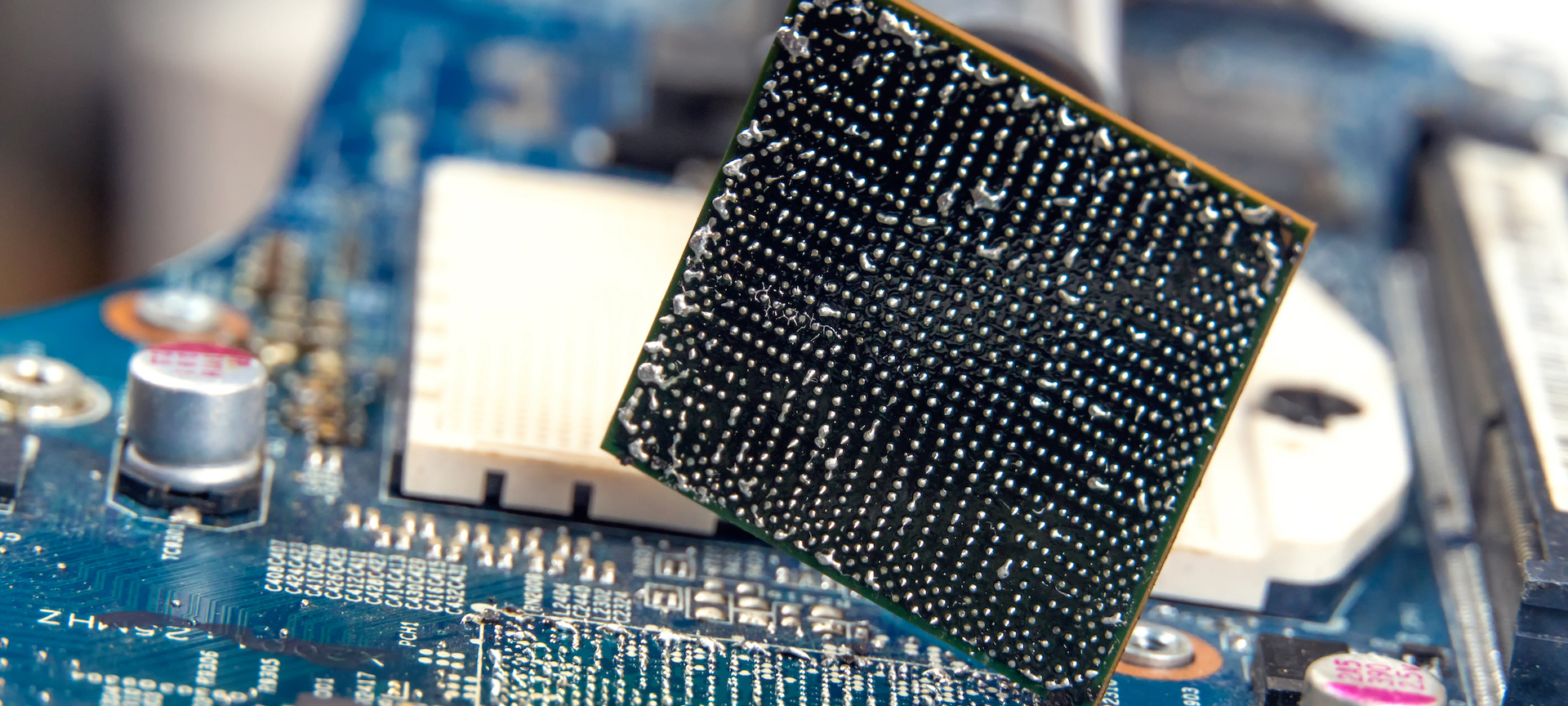

BGA Component Reballing Services

If you require Reballing services for your BGA component parts, you’ve come to the right place. Precision PCB Services can easily manage all your BGA component reballing needs. Contact us whenever you need BGA component reballing, and we will take care of you right away. We are also happy to answer any questions about the reballing process you may have.

What Is BGA Reballing?

In certain applications, you may occasionally need to change the alloy of your BGA component solder balls. Typically this means you have lead-free BGA component solder balls and you need them to be leaded for your applications. In this situation, your components will require reballing.

Our BGA Reballing Process

Precision PCB Services has a high-quality reballing process that conforms to IPC and JEDEC regulations. When you contact us for BGA component reballing with the sizes of your various BGA reballing packages and solder balls, we go right to work. We perform BGA reballing using the following step-by-step process:

- Prepping the BGAs: When we receive your BGAs, we remove the existing components and make sure the surface is clean.

- Securing the units: We place the units in a mold to keep them in place while we are performing the reballing.

- Introducing the stencil: The next step is to install a custom stencil built to match the size and spacing of your BGA in order to guide the solder balls.

- Securing the stencil: We then screw a ring on top to create a casing that keeps the stencil securely in place.

- Shaking in the solder balls: Thanks to the stencil, most solder balls will easily slide right into the divots of the component. We have a tool that can safely brush in any balls that do not make it into their slots.

- Reflow soldering: Next, we perform reflow soldering with a cutting edge reflow oven that gives us ideal temperature control and exposure for soldering. After a brief rest period, we deconstruct the fixture and clean off the leftover flux.

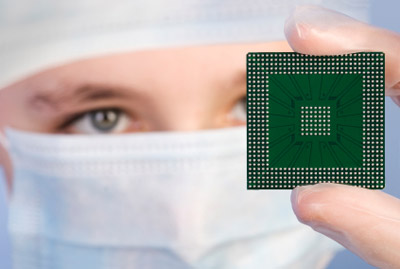

- Inspecting the results: Every reballing job we do is not over until we do a full, post-process inspection and verification. We analyze and test the entire setup to make sure all the balls are secure, imperfection-free and in the proper place.

Why Choose Precision PCB Services for Your BGA Component Reballing?

The “Precision” in Precision PCB Services is more than just a name. It reflects our commitment to performing accurate, high-quality work every time. We know that, when it comes to electronics, there is almost no margin for error, and we perform our services accordingly.

We also offer unparalleled customer service. You can call us anytime you are having trouble with your BGA package and we will walk you through solutions. We are the perfect partner to have in your corner. To inquire about reballing services, get in touch with us online today.

You'll need to reball BGA circuit arrays for various reasons, whether it's for technical problems, salvaging or reworking.

The process is relatively straightforward, but it requires high-quality components and a skilled hand to ensure you avoid any potential issues during the steps. Precision PCB Services has more than 20 years of experience helping customers of all kinds, making us confident in our ability to meet your specifications on a quick timetable.

We offer high-yield, cost-effective BGA reballing services. We can reball BGA devices of every size, pitch, and package style, including BGA, CGA, LGA, QFN, PoP and other complex packages. We stock the most common sizes of solder balls. From low volume to high volume BGA re-balling, we have fixtures and processes to meet all of your solder ball attach and re-balling requirements.