Lead Free Anomalies or Defects

Lead-Free anomalies or defects. Is your assembly yield less than 99%. I hope not. But if it is, you may want to consider this.

Since the advent of using Lead-Free Solders in assembly. Additional anomalies have come to light. The silver in lead-free solder tends to oxidize much more than lead solder. When using no-clean fluxes with an assembly process that does not implement either vapor phase or nitrogen. The silver in the solder solder when coming in contact with the raw air will cause a defect similar to Black Pad.

If BGA’s and other SMD's do not pass the electrical test.

It is important to inspect both the Component pads and the PCB pads for signs of oxidation and non-wetting after removal of the component. This normally will not be detectable by X-ray. It can cause anything from a weak signal to a complete electrical open.

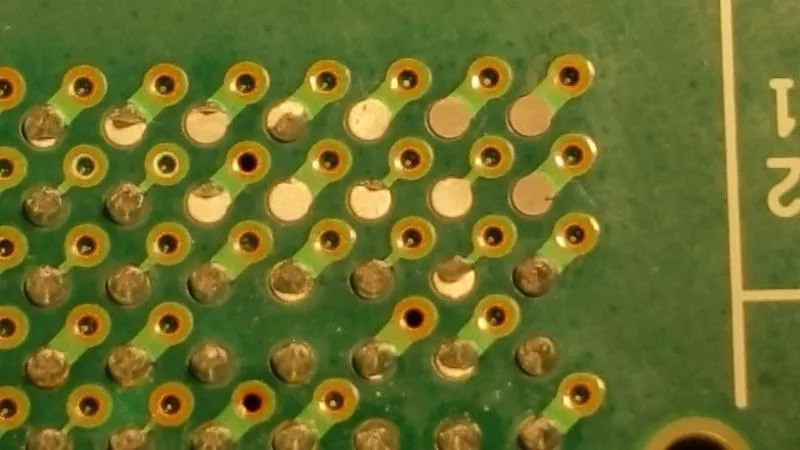

Below are illustrations of what the defect will look like.

Non-wetting at PCB caused by Oxidation.

Non-wetting at BGA caused by Oxidation

For best yields with Lead-Free Solder use an active flux. If you must use No-Clean Flux, then a Nitrogen or Vapor Phase Reflow Oven is best.