Solder Mask Repair Services

The solder mask on a printed circuit board (PCB) protects circuits from corrosion and prevents unintended bridges forming between elements. As an essential part of your PCBs, this epoxy coating needs to leave manufacturing facilities 100 percent intact.

Unfortunately, solder masks can become damaged or defective during or after the manufacturing process due to excess heat, improper adhesion and other problems. Though some manufacturers discard dysfunctional circuit boards, it's possible to recover their value by repairing or replacing the solder mask instead.

At Precision PCB Services, we perform solder mask repair, replacement and other services for PCB manufacturing companies and clients. Whether you need repairs for a large volume of circuit boards or just a few, we can take on the project. Learn what makes Precision PCB Services a strong choice for professional solder mask repair.

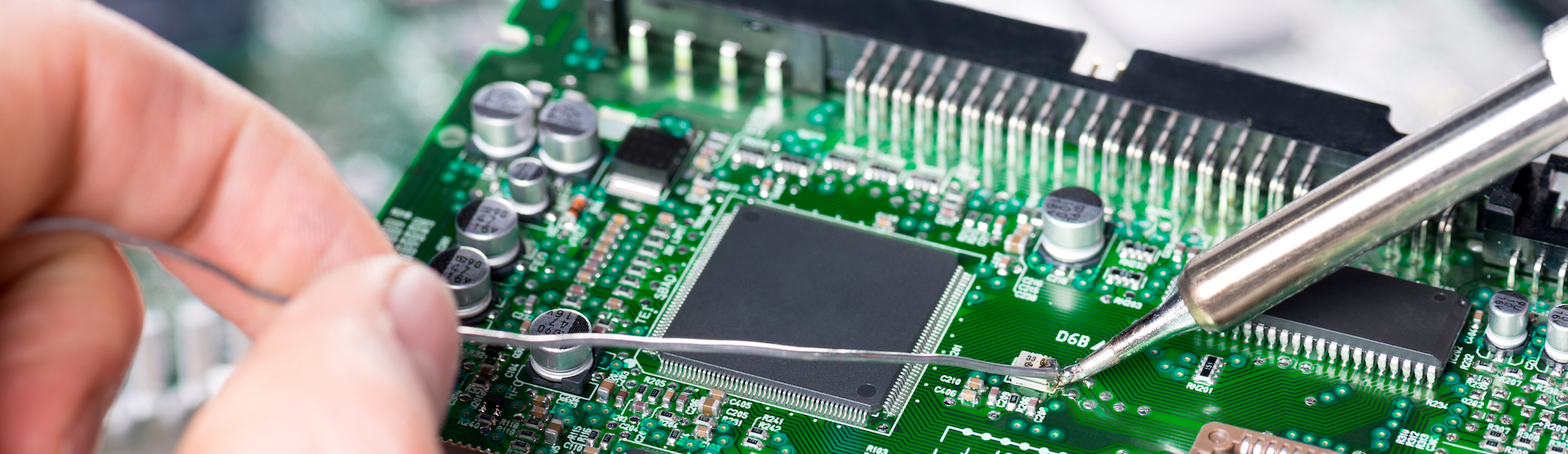

A Soldering Process to Produce Quality Results

Adherence to a proper solder mask repair process is essential to producing good results. At Precision PCB Services, we follow a series of steps to repair and replace solder masks and test for proper function:

- Clean and Examine the PCB Needing Repair: The first step in our solder mask repair process involves cleaning the surface to prevent oxidation and promote adhesion. While this occurs, we also examine the circuit board to identify the parts of the mask in need of repair.

- Remove Extra Solder: If necessary, we carefully remove excess solder from BGA pads and exposed traces before repair.

- Apply Solder Mask Replacement Material: Once clean and prepared, the PCB can receive a coat of replacement masking. If desired, we can match the color of the epoxy coating with the rest of the circuit board for a seamless look.

- Heat Cure the Coating: Finally, we cure the replacement coating. We use heat cured solder mask for a stronger bond.

After completing the replacement process, we perform visual checks and practical tests to ensure proper adhesion of the replacement mask and that every part of your PCB functions properly. We perform all solder mask repairs in accordance with IPC guidelines.

Soldering Services- An Experienced PCB Repair Team

Repairing circuit boards requires specialized training and equipment. Though some PCB manufacturers and electronics companies repair PCBs internally, many lack the resources necessary to dedicate staff to repair processes.

Precision PCB Services is a dedicated PCB repair and support operation. With more than 25 years of experience and a team of highly trained repair professionals, we're capable of tackling solder mask repair and replacement projects others can't, like solder bumping a substrate.

In addition to professional repair services, we can also provide employee training so your company can start employing in-house, dedicated repair technicians, as well. If you find your solder masks in need of repair often, you might also use our consulting services to find flaws in your manufacturing process and decrease the need for repairs overall.

If you're looking to outsource solder mask repair to a dedicated repair company, Precision PCB Services can help. Contact us today to learn more about our coating replacement process and other soldering service capabilities.