Lead-Free Soldering Class

Driven in part by European Commission (EC) and Waste from Electrical and Electronics Equipment (WEEE) directives, as well as legislation in numerous parts of the world directly banning lead-based soldering, many manufacturers and reworkers of electronics equipment have had to rethink how they approach their soldering techniques without the use of lead or a lead alloy.

Interestingly, due to the Internet of Things (IoT) and the subsequent rise of smart devices and appliances, printed circuit boards (PCBs) are now in use far beyond PCs, laptops and smartphones. This change means that everyone from major appliance to automotive manufacturers — and those in their electronic equipment supply chains — are in a position where transitioning to lead-free soldering techniques will keep them marketable and competitive for the future of their respective businesses.

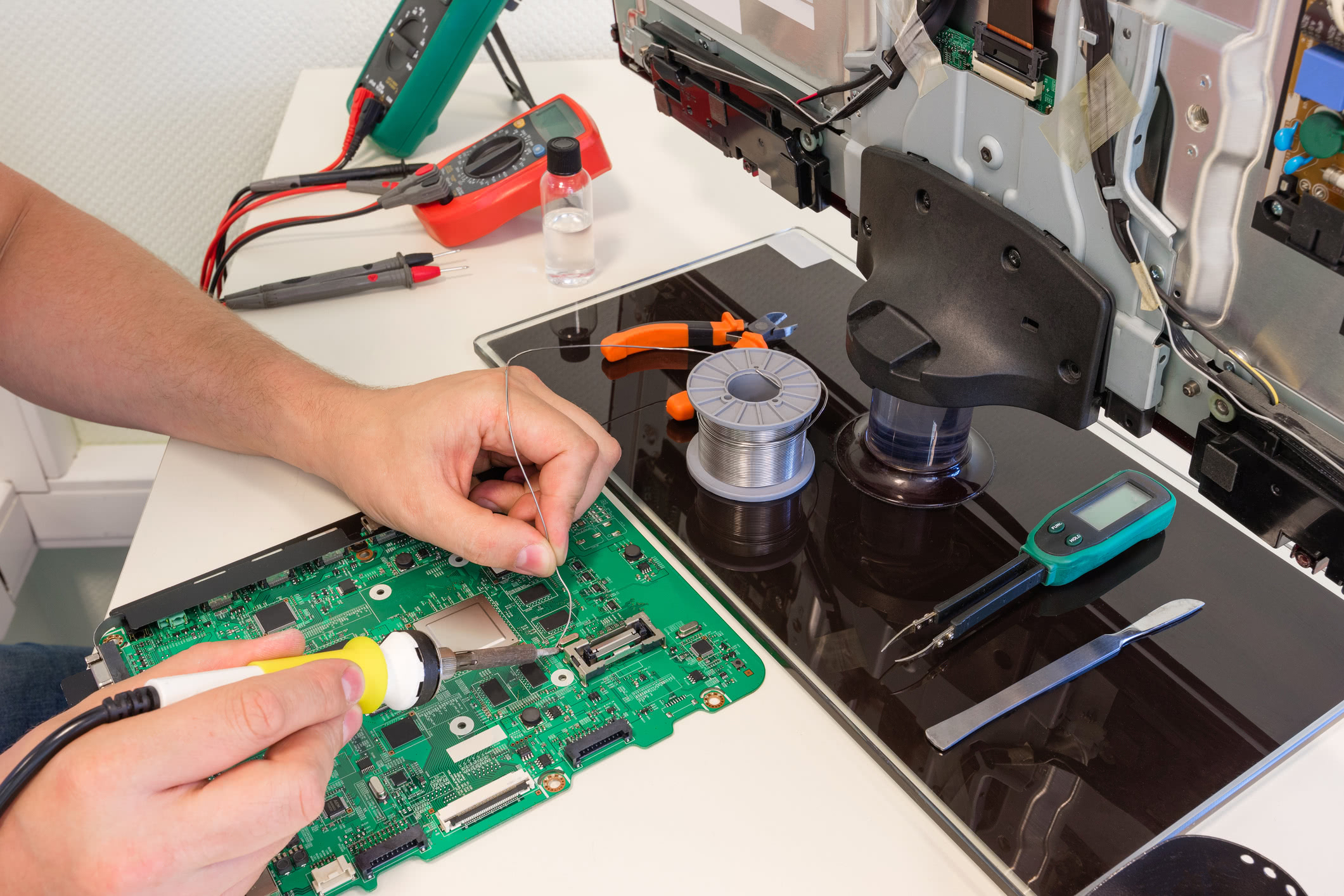

For these reasons, Precision PCB Services, Inc., with over 25 years of electronic equipment training and consulting experience, is offering lead-free soldering classes featuring hands-on lead-free soldering training and certification. These classes are specifically designed to help you acquire the skills necessary to make lead-free solders that meet all of the PCB assembly requirements and performance standards of your industry.

What Is a Lead-Free Soldering Workshop?

Since lead-free soldering isn’t a one-size-fits-all solution, training is highly recommended so that both the knowledge of different types of lead-free solder — as well as the necessary skills and techniques to use them at appropriate temperatures — are acquired under watchful instruction.

In addition, to fully meet with industry standards, all of our lead-free solder training and solder certification courses are taught in accordance with IPC soldering guidelines.

How to Get Soldering Skills Training and Certification

This one-day, hands-on course highlights and explains the differences between lead-free and tin-lead solder — for solder joint touch up and rework.

Topics covered include:

- Flux considerations

- Component removal

- Land preparation

- Component replacement

- Correct methods for touch up and rework

- IPC Guideline for solder joint evaluation

Hand soldering techniques for Surface Mounted and Through Hole Devices include:

- Point-to-point soldering

- Drag soldering

- Touching up joints with too little solder

- Solder bridge removal

- De-soldering techniques for SMT and PTH components

Additional topics covered include why companies are making the switch to lead-free processes, the characteristics of lead-free solder alloys and lead-free solder joint evaluations — during which target, acceptable and unacceptable lead-free joints are compared to their tin-lead counterparts.

This course is designed with rework technicians in mind. It aims to help them make the lead-free switch with knowledge and confidence.

- Price: $550.00 per student.

- Maximum students allowed at our facility: 5 or fewer attendees.

- Maximum students allowed at customers facility: 25 or fewer attendees.

Contact Us to Learn More About This Lead-Free Soldering Training

This course is provided at our Plano, Texas, and Oroville, CA, locations, or at the customer’s facility. A $10,000 minimum cost for 10 or fewer students will be charged for any classes held at the customer's facility. Additional fees apply for travel expenses if we’re required to travel in excess of 70 miles from our location. Classes offered at our facility do not have a minimum requirement and can be scheduled as needed.

Every course includes a Certificate of Completion. To reserve your class, remember that advanced payment is required. Accepted payment methods include Visa, MasterCard, American Express, Diners Club, company check or EFT. Call Today to learn more.