WDS 900 BGA Rework Station

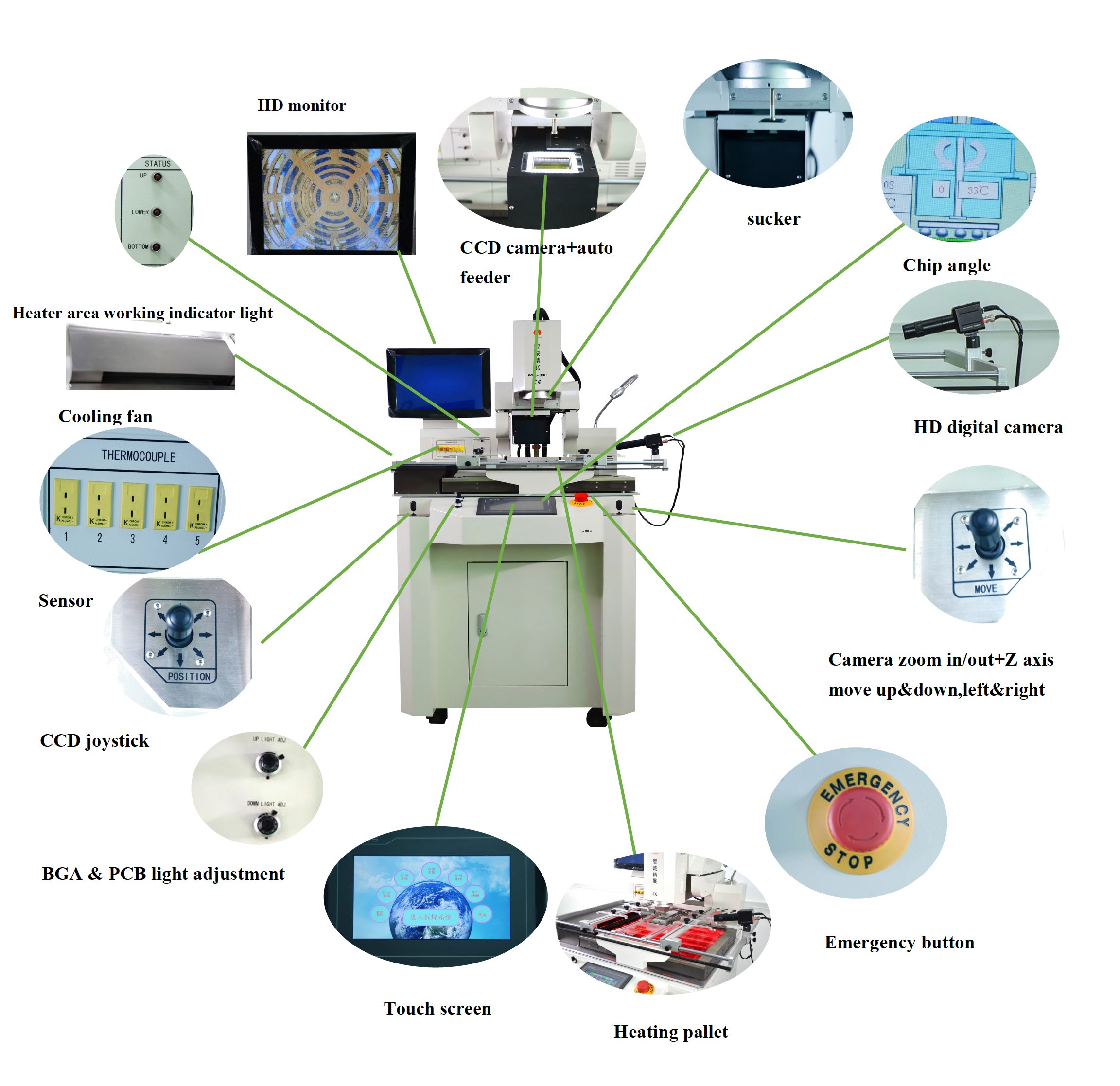

WDS-900 BGA Rework Station

Features:

- Motorized Optical System

- Siemens PLC control

- Rapid Heat Area Heater

- Touch Screen Operation and Programming

- Nitrogen or Compressed Air Optional

- High Resolution Optical System

- Removable optical fast positioning system

- Auto feeder system

Accessories Include:

- BGA Rework station 1 set

- Titanium alloy hot air nozzle 7pcs

- T type nut and screw 4pcs

- Red brush 1pc

- Plum handle 8pcs

- HD monitor 1set

- TManual Book 1copy

- Universal Fixture 8pcs

- Red suction cup 4mm/8mm 10pcs

- suction nozzle 2pcs

- Temperature line 5pcs

- Tool box 1pc

Operation Control System

- Auto soldering&desoldering chip

- Siemens PLC control

- Optional operation modes

Independent Temperature Control System

- Up&down air pressure heating control 1200 w

- Siemens PLC control display temperature curve in the current time, showing set curve and practical curve, it will analyze the tempo curve on the screen.

- Infrared tube 3independent heating area every area can set heating temperature、heating time、speed of heating temperature;10 heating period simulate reflow heating more set as pre-heat, heat preservation, heating, weld, reflow, cooling.

- Adopted America high precision K-type thermocouple close-loop control, special heating way, soldering temperature precision control within 1℃ .5independent sensor, detection chip melting temperature accurately, ensure soldering success rate.

Precision Optical Alignment System

- Color optical system with the function of split vision,two-color separation, zoom in/out, and micro-adjust, equipped with aberration detect the device, with autofocus and software operation.

- auto soldering/desoldering and feeding system.

Superior Safety System

- CE certificated

- With automatic power-off protection device when an abnormal accident happens, with a double over heating protection control

- Temperature curve with password protection authority avoids non-operator to changing parameters.